Enhancing Flexo Printing Process with Advanced Static Control

Integrated static control boosts performance and profits for customers

Nilpeter Asia Pacific Co. Ltd, a leading OEM in the printing industry and Fraser Anti-Static Techniques’ distribution partner in Thailand, has been collaborating with Fraser for many years.

Throughout this partnership, Nilpeter has relied on Fraser’s static control equipment to ensure optimal performance in its flexo printing machines. In a recent development, Nilpeter Asia Pacific Co. Ltd, launched its own innovative non-contact web cleaner, the FlexClean, which integrates Fraser’s 1100 AC anti-static bars.

The problem

Flexo printing is widely used across industries for high-quality label production, packaging, and more. However, one significant challenge in this process is controlling static electricity, which can attract dust and particulate contamination during the web handling process. This contamination compromises print quality, leading to rejected products, production delays, and increased costs. For a company like Nilpeter, whose reputation depends on high-quality output, cleaning the web and then controlling static is critical to maintaining performance and customer satisfaction.

To address this challenge, Nilpeter needed a static control solution that could seamlessly integrate into its newly developed web cleaner, FlexClean, to provide their customers with cleaning capabilities with enhanced static control.

The solution

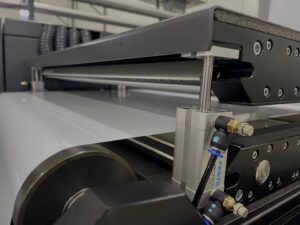

The Fraser team worked alongside the team at the Asia branch to identify the best technology available to integrate into the existing set up. The 1100 AC anti-static bars were selected to be integrated into Nilpeter’s new non-contact web cleaner, FlexClean.

The FlexClean system uses airflow to remove contaminants, while the anti-static bars neturalise the web and contamination to improve the cleaning effect. Further static control maintains the low level of static charge to prevent recontamination.This means that once installed into their FA-Line flexo press, Nilpeter can offer their customers a system with increased performance and operational efficiency.

The Fraser 1100 AC bars are known for their reliability and performance in demanding industrial applications. By delivering a controlled balance of positive and negative ions, these bars effectively neutralise static at the source, preventing electrostatic attraction and enabling a cleaner production environment.

The results

The implementation of Fraser anti-static technology into the Nilpeter systems has resulted in significant improvements in print quality and reduced waste.

Nilpeter Asia can now offer its system to customers with a number of additional benefits:

- Reduced product rejection rates due to better contamination control

- Improved production efficiency and reduced waste through effective static neutralisation

- Enhanced print quality by eliminating static during the web handling process

Conclusion

The partnership between Nilpeter and Fraser Anti-Static Techniques highlights the importance of combining industry-leading expertise with cutting-edge technology. The integration of Fraser’s 1100 AC bars into Nilpeter’s FlexClean system has resulted in a powerful, non-contact web cleaner that ensures high-quality production and improved efficiency. This collaboration continues to strengthen both companies’ positions in the market, driving innovation and delivering value to customers across the printing industry.

Want to find out more? Get in touch with our team sales@fraser-antistatic.co.uk

Last Updated: 20 February, 2025