Reducing Particle Contamination and Quality Issues

Fraser 24V DC and AC Static Bars use Air Assistance to Prevent Contamination

Many processes involved in the manufacture of medical equipment and pharmaceuticals products generate static electricity. This challenge is often intensified by low humidity levels and the presence of flammable solvents or fine powders.

Fraser Anti-Static Techniques delivers static control solutions worldwide through its network of distributors across five continents. One of Fraser’s South Korean distributors, IONCRAFT has recently supplied a company with Model 3014-AIR and 1250-AIR Bars that prevent contamination and quality issues in blister packaging.

THE PROBLEM:

Company YOOYOUNG Pharm. Co., Ltd require strict quality control in their blister packaging process. Static charges were attracting foreign particles, posing risks of contamination and quality issues.

YOOYOUNG Pharm. are a global healthcare company manufacturing prescription drugs and medical devices.

THE SOLUTION:

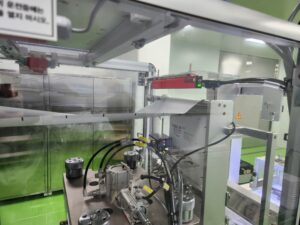

IONCRAFT evaluated the production process and installed a Fraser 24V DC 3014 Bar with Air Assistance and a custom-integrated acrylic cover to block particle intrusion. A Fraser AC 1250-AIR Bar was also installed in another area to further eliminate foreign particle risks.

THE OUTCOME:

• Effective prevention of contamination in tablet packaging.

• Support for maintaining GMP-level clean production environment.

• Stable operation since installation, with positive prospects for future expansion.

CUSTOMER FEEDBACK

“Since installation, production stability has improved significantly, and concerns over static-related defects have been minimised. We will appropriately consider Fraser products for future installations.”

Last Updated: 5 November, 2025