Driving down waste with static control

Specialist static control solution delivers 75% reduction in product rejection.

Fraser Anti-Static Techniques worked in partnership with global automotive business Valeo on a project spanning sites across the world, devising a system to reduce particle contamination on the production line caused by static, and in turn reduce product rejection rates.

Valeo is an automotive supplier and partner to automotive manufacturers worldwide. The Group employs 113,600 people in 29 countries worldwide and has 186 production plants.

It designs innovative solutions for smart mobility, with a particular focus on intuitive driving and reducing CO2 emissions. The Group also provides and distributes spare parts for automotive and independent aftermarket operators.

Importantly for Valeo, given its sustainability focus, the project was key in reducing waste. Working together with Fraser’s Spanish distribution partner ElectrostatEx and French distributor SOREPRIND, the teams devised an effective solution for a complex problem that had a major impact on productivity and waste reduction.

THE PROBLEM

Airborne particulate contamination was affecting the production of complex 3D polycarbonate parts.

The complex multifaceted 3D shapes meant tackling any particulate contamination was more challenging. Part of the production process involved components being bonded together. Particulate matter getting inside of the unit before sealing was causing products to be rejected.

Furthermore, this was happening at a late stage of the production process where the products were almost complete, meaning that any contamination and subsequent rejection of parts was very costly in terms of reduced profit and increased waste.

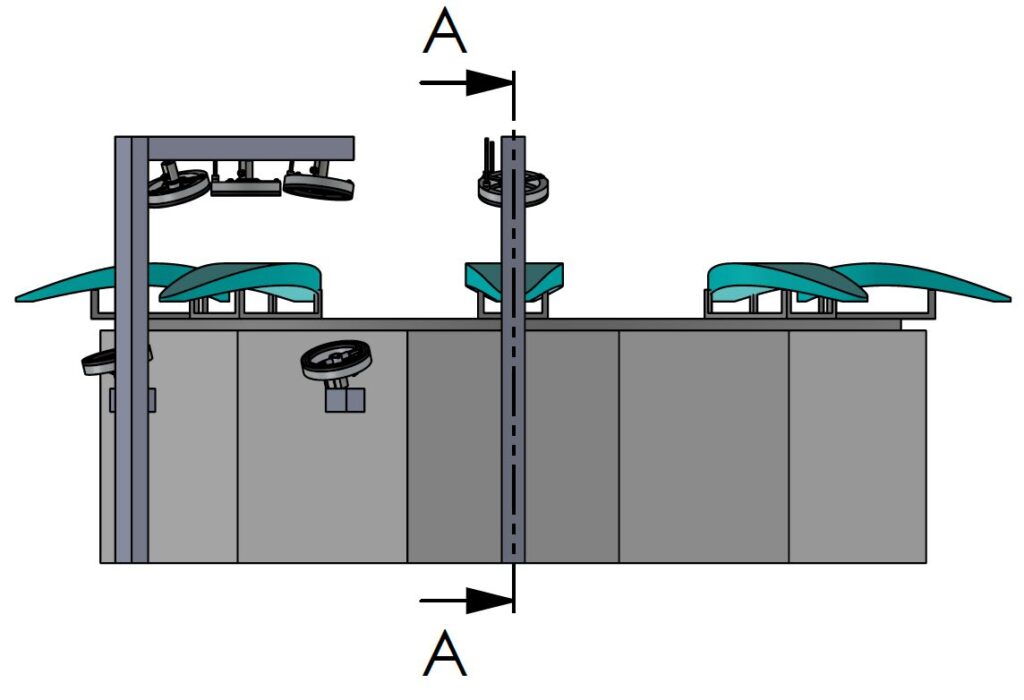

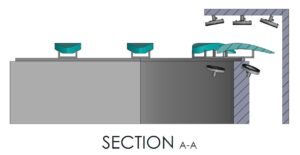

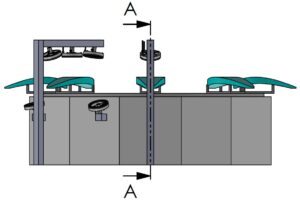

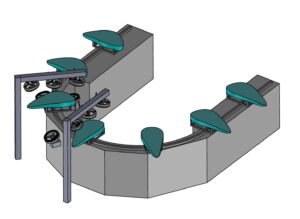

Fraser Roto-Clean units strategically positioned above and below the Valeo production line.

THE SOLUTION

A very specific static control solution was needed. Typical manual static control solutions such as bars and guns were not enough to ensure the cleanliness of the complex shapes prior to the bonding and sealing process.

Easy to install and flexible mounting options for seamless integration.

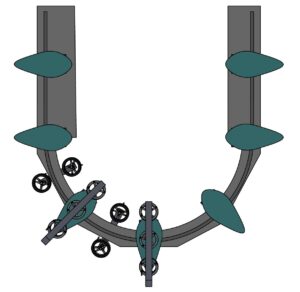

The Fraser team designed an automated solution using its 4900 Roto-Clean. This device combines an advanced circular ioniser with high speed, twin air-powered rotating jets to create a uniquely effective tool for removing dust and contamination from industrial parts.

The Roto-Clean creates a pulsed ionised air flow. The pulsing action is highly effective for particulate removal from 3D parts.

THE RESULTS

There was a 75% reduction in the product rejection.

This has had a significant impact on cost and time saving and waste reduction.

International Technical Manager at Fraser, Jason Morgan said: “We love a static challenge. Working closely with our Fraser partners and Valeo was vital in solving this complex problem as we needed to understand the parts and production process in detail to be able to recommend the right solution. We are delighted with the results that Valeo has achieved using the Roto-Clean.”

Fraser’s Roto-Clean is used by manufacturers across the world in many other applications, particularly where the problem involves complex shapes that require a specialist static solution.

Highly effective, non-contact dust removal and static neutralisation from automotive components on a conveyor

Experiencing dust related product rejects? Contact the Fraser team at sales@fraser-antistatic.co.uk or visit the website for more information.

Last Updated: 4 October, 2024