What are the Causes of Static Electricity in Manufacturing?

What are the Causes of Static Electricity in Manufacturing?

The main causes of static electricity are:

- Contact and separation between two materials (including friction, travelling over rollers, etc)

- Rapid heat change (e.g. material going through an oven)

- High energy radiation, UV, X-ray, intense electric fields (not very common in industry)

- Cutting action (e.g. a slitter or sheet cutter)

- Induction (standing in the electric field generated by a static charge)

1. Contact and Separation

Contact and separation is probably the most common cause of static in industry where film and sheet are being processed. It happens when material unwinds or passes over a roller. This process is not fully understood, but the clearest explanation of how the static is generated here is an analogy with a plate capacitor where mechanical energy to separate the plates of a capacitor is converted into electrical energy:

| Starting Voltage x Resultant distance between plates | |

| Resultant Voltage = | ----------------------------------------------------------- |

| Starting distance between plates |

When the material touches the roller, a small charge flows from the material to the roller causing an imbalance. As the material leaves the roller the voltage is magnified like the separating plates of a capacitor.

The size of the resultant voltage is limited in practice by the breakdown strength of the surrounding materials, surface conduction, etc. You often hear small crackles, or static discharges, as the material leaves the roller. This is where the static has reached the breakdown strength of the surrounding air.

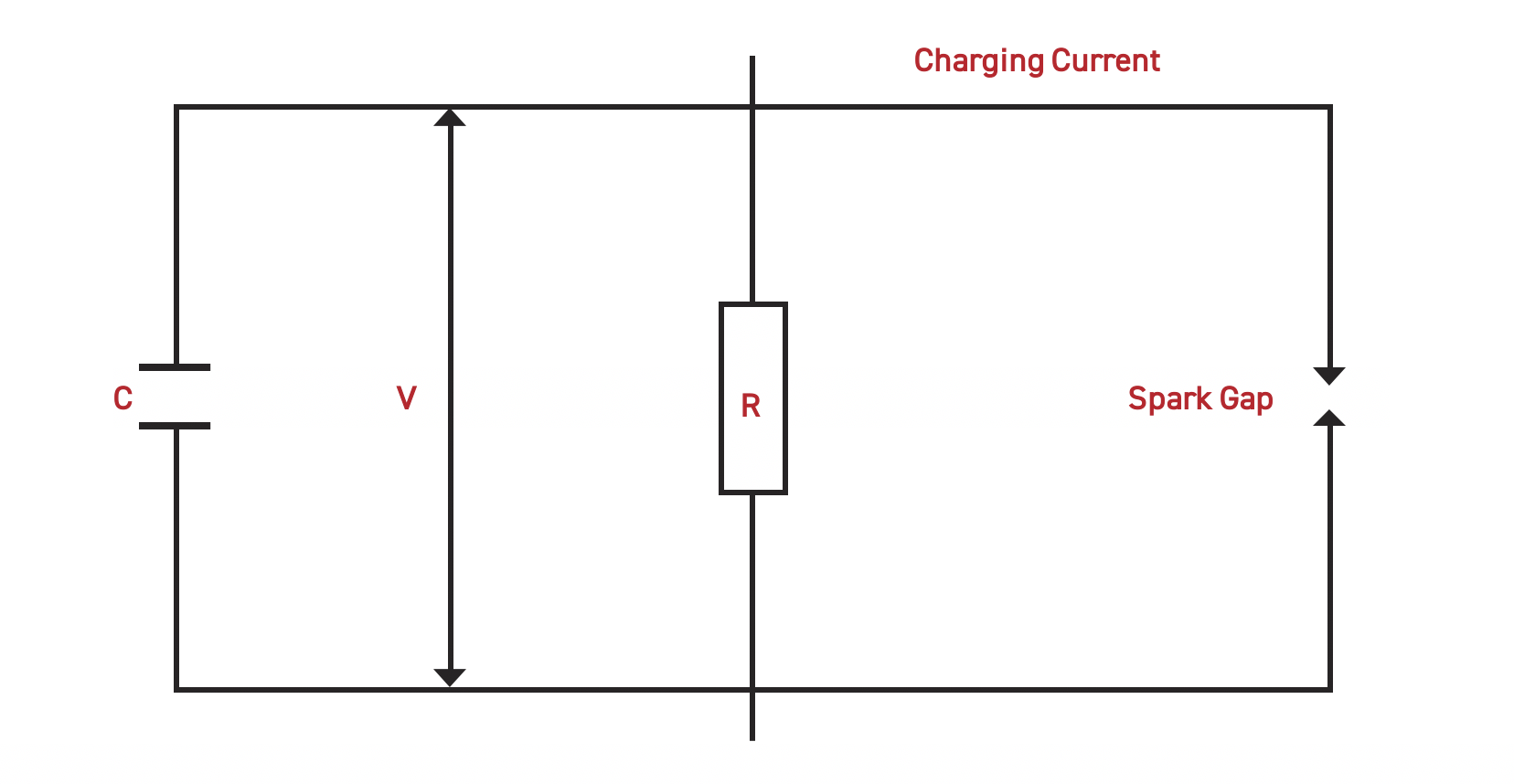

In theoretical terms, a static charge can be represented by a simple electrical circuit:

C is the capacitor function which stores the charge, like a battery. It is usually the surface of the material / product.

R is the charge relaxation ability of the material / system - usually a small current flow. If the material is conductive the charge will escape to earth and so will not become a problem. If the material is non-conductive, the charge cannot escape and so can become a problem.

The Spark Gap is the limit to the voltage build-up.

The charging current is the charge generated by the action of the product over a roller etc.

The Charging Current charges up the capacitor (i.e. the product), increasing its voltage V. As the voltage increases, current flows through the resistor R. An equilibrium will be reached where the charging current is equal to the current flowing through the resistor.

(Ohms Law applies here: voltage = current x resistance)

A static problem arises when the product is able to store a sizeable charge and a high voltage is present. The static problem will show itself in the form of a spark, electrostatic repulsion/attraction or shocks to operators.

Polarity of the Charge

The static charge may be positive or negative. For AC static eliminators and passive dischargers (brushes) the polarity of the charge is not usually important.

2. Rapid Heat Change

Pyroelectricity is the term used to describe the ability of certain materials to generate static when they are heated or cooled. Plastic mouldings are particularly prone to developing a static charge while they cool after moulding or subsequent heat treatment.

A plastic product is not electrically stable until it is relatively cool: 40º - 50º C is a typical target figure for electrical stability.

3. High Energy Radiation

Although not so common in industry, exposure to UV, X-rays or intense electric fields can cause a static charge to develop. Plastic films that have been subjected to Corona treatment to improve printability will often exhibit unwanted levels of static electricity.

4. Cutting Action

Sheet cutting or slitting and trimming processes will generate a static charge. On an individual sheet basis, this may not be too much of a problem, but when multiple sheets or components are stacked, the ‘battery effect’ can produce a significant and problematic static charge.

5. Induction

If an operator, wearing insulative shoes, stands within the field of a static generative process then moves away and touches an earthed structure, they can experience an uncomfortable but generally harmless static discharge.

This can be dangerous not because of the electric shock itself but due to the uncontrolled ‘recoil’ reaction of the operator.

Last Updated: 27 November, 2020