Measurement of Static Electricity

Measuring static electricity is important. It allows you to see if there is a static charge present, its size and where it is being generated.

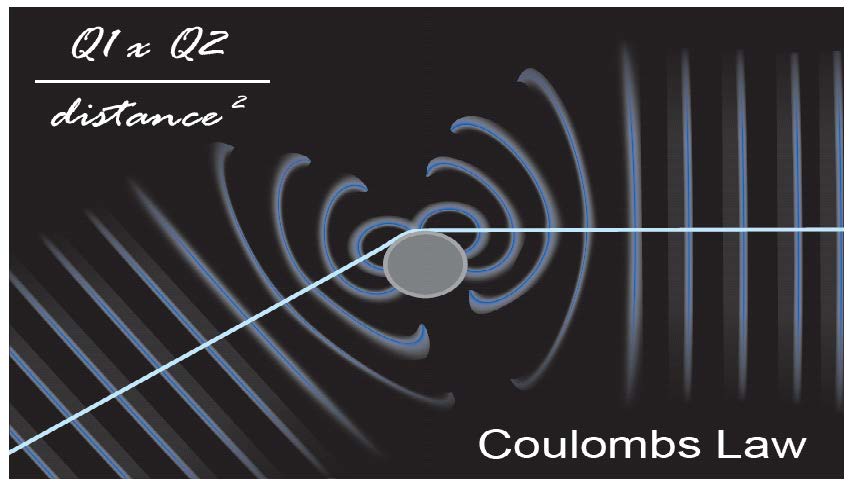

Static electricity is a surplus or deficit of electrons which is measured in Coulombs. As it is not possible to measure the charge in a material in Coulombs, the electric field strength or surface voltage related to the static charge is measured. This is the accepted method of measuring static in industry.

The relationship between the field strength and voltage is that the former is the voltage gradient at any point.

Measuring Surface Voltage

Fraser 715 Static Meters measure surface voltage. They use the following circuitry:

The voltage across this capacitor varies directly with the charge.

Using Q (charge) = C m (capacitance) x V (voltage), the capacitance is set at the measuring distance of 100 mm. This means that the charge Q varies directly with the voltage V.

Fraser meters are simple to use and very useful in analysing problems. The 715 Static Meter is ideal for non-hazardous environments. Where EX hazardous areas exist, Fraser has the only ATEX certified static meter, the EX-715. Safe for Zones 1 and 2, this meter has ATEX and IECEx certification.

It is important to follow Operating Instructions when measuring static. The electric field behaves in unique ways and must be understood. One of the most interesting characteristics of the electric field, which is very important when trying to measure the charge, is shown below.

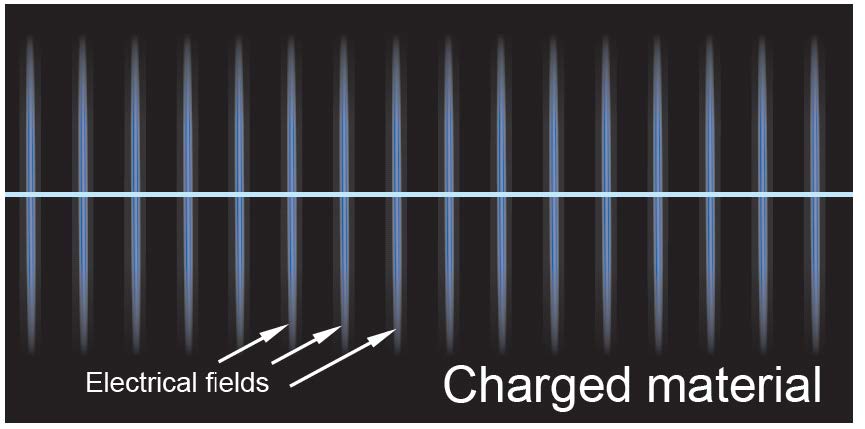

Electric Field:

- is a region of space in which electrical (Coulomb) forces act

- every charged object is surrounded by an electric field

- the field lines run perpendicular to the material and show the direction in which the force acts

- it can be coupled with other bodies with important consequences for measuring and neutralising the charge

The electric field lines run perpendicular to the charged material when it is in open air. When the electric field is like this it is easy to make accurate and intelligent measurements.

When the charged material passes over a roller, the electric charge couples with the roller and seems to disappear. It is impossible to make an accurate measurement near the roller. The electric field ‘returns’ when the material leaves the roller and so can be measured again.

Measuring Surface Resistance

For the temporary electrostatic adhesion of two materials to be effective, at least one of the materials must be a good insulator. Two conductive materials will not stick together because they will not hold the static charge. The insulator must be an electrical barrier to the static charge. Normally the insulator is a plastic film or sheet and there is not a problem with the adhesion.

With other materials, like paper, there can be a problem. Dry paper can be a good insulator, but if it becomes damp it quickly becomes more conductive and stops being an effective electrical barrier.

The critical level of surface resistivity is 1010 Ohms/Square. If the resistance is below this figure, then good electrostatic adhesion is not possible. Above this level, it begins to be an electrical barrier but is not a good barrier until it reaches 1012 Ohms/Square. The hand-held Fraser 740 Surface Resistance Meter is ideal for measuring this and also the resistance to earth as needed.

Measuring Liquid Conductivity

The motion of low conductivity liquids, such as fuels and solvents, can result in the generation of hazardous levels of static electricity. Stirring, pouring and, in particular, flow through metal or plastic pipes, are all examples of industrial operations, which can produce ignition, fires and explosions.

These operations and others are covered in International Safety Standards. In these Standards, references are made to conductivity values, and the importance of routine liquid conductivity measurement in controlling ignition hazards is emphasised.

Liquid conductivity is inversely related to the time it takes for charge on the liquid to dissipate to earth and a low conductivity implies a long charge relaxation time. This in turn leads to a higher risk of producing an ignition.

The Fraser L40 Liquid Conductivity Meter out-performs many instruments by measuring electrical conductivity to below 1 pS.m-1 (picoSiemens/metre); this is an essential requirement for determination of ignition hazard.

It is crucial when dealing with flammable fuels and solvents of conductivity less than 500 pS.m-1 to consider measures to combat electrostatic ignition hazards. Such measures should not be necessary with relatively conductive liquids greater than 500 pS.m-1.

Measuring an Electric Charge in an Anti-Static Bar

It can sometimes be difficult to tell if an ionising bar is still working. Designed specifically to test the functionality of AC static elimination equipment, the Fraser 720 Static Bar Checker is simple to use, accurate and reliable. A working bar will induce an electric charge on the internal sensor of the 720 which in turn will illuminate between 1 and 5 LEDs depending on performance.

Last Updated: 27 November, 2020